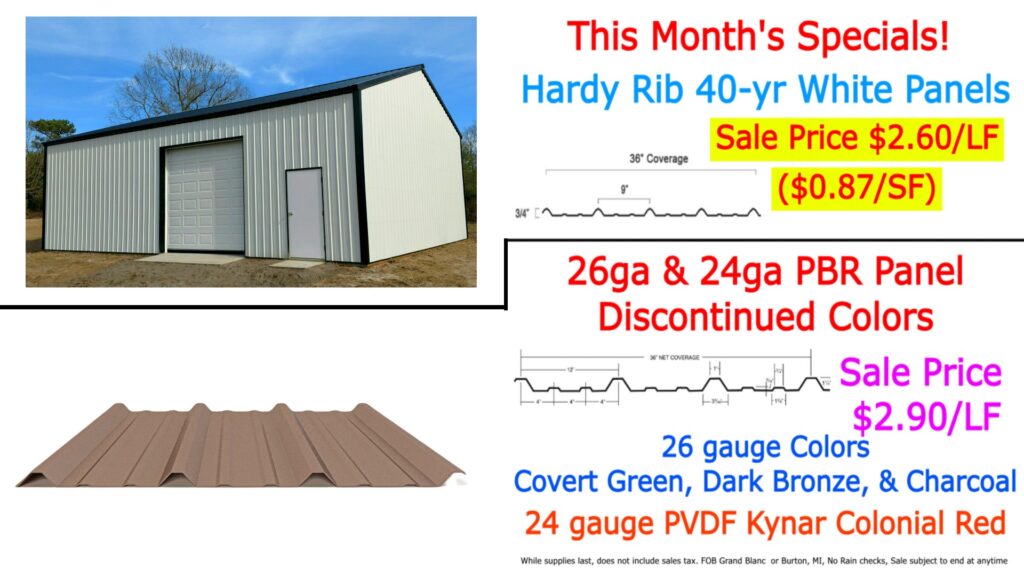

Hardy Rib: Premium Metal Roofing Materials

Home » Metal Roofing Panels » Exposed Fastener Steel Roof Panels » Hardy Rib

Hardy Rib Metal Roofing Panels

The Hardy Rib Premium Panel is a very affordable option for roofing or siding and typically runs less than standard asphalt shingles. All Hardy Brand products are made with steel that is code compliant for residential steel roofs in the State of Michigan.

Not all Steel Roofing is Created Equal. Make an Educated decision. Learn more Here.

- Can be installed over an asphalt shingle roof**

- 16 standard colors in stock (in coil form)

- 4 Textured Paint colors in stock. (See below for more info.)

- 4 Woodgrain 28 gauge colors in-stock (lead time may vary)

- 2 Stackstone 26 gauge colors in-stock (lead time may vary)

- 29 gauge (.015″ minimum thickness before paint)

- Made Standard in #1 Prime AZ50 Galvalume® Steel.

- G-100 Galvanized Steel is available for buildings used for animal confinement. (12 colors options, special order)

- Structural strength ASTM-A792, grade 80 steel.

- UL 790 Fire Resistance Class A

- UL 2218A Impact Resistance Class 4

- Code Compliant for Michigan Residential Building Code.

- Weighs on average 68 lbs per 100 sq. ft.

- Iron Clad 40-year Paint and Lifetime Steel Warranty.

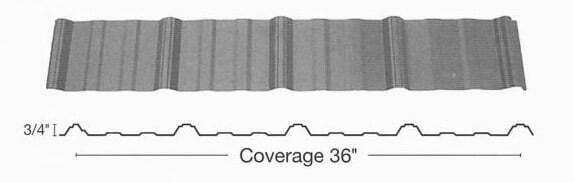

- 36″ wide nominal coverage.

- Made in sizes 3ft to 50ft, cut to the whole inch.

- Exposed Fastener Panel System.

- Order production time: 1-2 business days for standard colors*

- Quote and buy online. Click here.

The Hardy Rib Premium Panel has a deep channel anti-siphon rib to prevent capillary action, along with five 3/4″ major ribs and eight minor ribs to decrease oil canning. This panel is similar in design to Premium Pro Rib®, Classic Rib®, Tuff Rib®, Ultra 2000, 5Rib, Master Rib, and many more. The Hardy Rib panel design is the most commonly used steel roofing panel design in the residential roofing market. This is because of its amazing benefits including low cost, low maintenance, superior longevity, high wind rating, and ease of installation, just to name a few.

The Hardy Rib Premium Panel can be installed over your existing asphalt shingle roof without compromising the longevity of your new metal roof. (Check with your local building codes for installing another layer of roofing over your existing roof.) If you decide to install your new metal roof over your existing asphalt shingles, we recommend using 1×3 purlins or 2×3/2×4 purlins. As an alternative, you can install synthetic felt or 1/4″ fan fold foam over your existing shingles. The most important thing when installing metal roofing over an existing roof is you must have a permanent vapor barrier between your existing shingles and your new lifetime metal roof. The reason for a permanent vapor barrier is simple. The granules from the asphalt shingles will scratch the backside of the panel causing premature failure and will void the warranty on the panel. (Do not use saturated felt paper as a vapor barrier. Saturated felt is not considered a permanent vapor barrier.)

All Hardy Rib Premium Panels come with an exclusive Iron Clad 40-year Paint & Lifetime Steel Warranty.

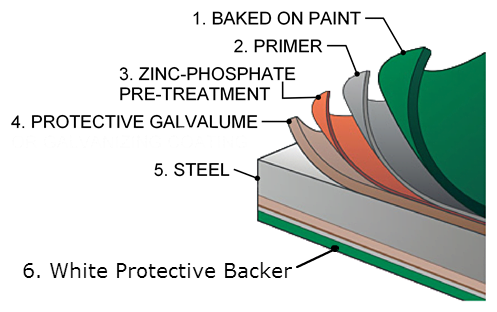

Our Hardy Rib panel is made from #1 premium steel and painted with Sherwin Williams Weather XL paint system. Learn more about the paint system we use at the bottom of this page. The Hardy Rib Premium Panel has eight layers of coatings to complete the paint system. It also features an exclusive 40-year paint & lifetime steel warranty. With the best warranty and paint coatings available in the industry, you will know your home will be protected from the elements for over a hundred years.

The HardyRib Premium Panel can be purchased in-store, over the phone, or via our online store. Click here to shop now.

*Buy today. Pickup tomorrow/24 hour turnaround time starts after the order confirmation has been signed. Lead time applies for HardyRib or EconoRib panels picked up from our Burton, MI location. Depending on the time the confirmation is signed, type of trims ordered, and current color availability, additional lead times may apply.

**Contact your local building department to determine if a tear-off is required.

Looking for a WoodGrain or Stone Look? We have you covered!

Woodgrain steel siding panels combine the natural aesthetic of wood with the durability and low maintenance of steel. These panels are designed to replicate the warmth and texture of real woodgrain while providing enhanced performance and longevity. Available in various profiles and colors, they are ideal for residential, commercial, and agricultural applications.

Wondering how HardyRib Panels are made? Watch the video below.

Additional Product Information

Use this table to determine appropriate fastener distance based on your live load and wind load requirements.

Industry standard for the State of Michigan is 24 inch span.

Span (Inches) | 18″ | 24″ | 30″ | 36″ | 48″ | 54″ | 18″ | 24″ | 30″ | 36″ | 48″ | 54″ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

29 Gauge | 199 | 112 | 71 | 49 | 28 | 22 | 211 | 118 | 76 | 52 | 49 | 23 |

Notice:

1. Theoretical allowable loads are based on section properties and allowables calculated in accordance with 2001 AISI Specifications.

2. Theoretical allowable loads are based on three or more uniform spans.

3. For roof panels, deduct self weight for actual ‘live load’ capacity of the panel.

4. These loads are for panel strength. Frames, purlins, decks and fasteners must be designed to resist all loads imposed on the panel.

Installation Guide, Standard Trims Book, and Color Chart Downloads

Downloadable Installation Guide (PDF)

Downloadable Standard Trim Pieces (PDF)

View the Color Chart & Color Matrix (PDF)